2025 Top Jack Leg Rock Drill Innovations: Features and Best Practices

In the realm of mining and construction, the Jack Leg Rock Drill has established itself as a vital tool, renowned for its versatility and efficiency. As we approach 2025, the innovations surrounding Jack Leg Rock Drills are set to redefine industry standards, integrating advanced technology and ergonomic designs aimed at enhancing productivity. According to a recent Market Research Report, the global rock drilling equipment market is expected to witness a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028, driven by the increasing demand for infrastructure development and mineral extraction.

Leading industry expert Dr. Samuel Keith, a renowned geotechnical engineer, emphasizes the importance of innovation in this sector: "As we look towards the future, the Jack Leg Rock Drill must evolve to meet the dynamic needs of mining operations while prioritizing operator safety and environmental sustainability." This statement underpins the focus on developing features that not only optimize performance but also adhere to modern safety standards.

As we delve into the latest features and best practices of Jack Leg Rock Drills in the upcoming sections, it becomes imperative to explore how these innovations can address the challenges faced by operators, ultimately shaping a more efficient and safer work environment in the industry.

2025 Innovations in Jack Leg Rock Drills: An Overview of Advanced Features

As we move towards 2025, the jack leg rock drill evolves with several remarkable innovations aimed at enhancing efficiency and safety in mining operations. These advanced features not only increase productivity but also significantly reduce operator fatigue and potential hazards on the job site. Key innovations include advanced hydraulic systems for better torque control, improved dust suppression technologies, and ergonomic designs that cater to long days spent underground.

One of the standout features of modern jack leg rock drills is the integration of smart technology. Many drills now come equipped with sensors that monitor performance in real time, providing data on drill pressure, temperature, and operational speed. This allows operators to make immediate adjustments, ensuring optimal performance while extending the lifespan of the equipment. Additionally, lightweight materials are being used in drill construction, making them easier to handle without compromising strength.

Tips: When investing in a jack leg rock drill, consider models that offer customizable settings to suit specific drilling conditions. Regular maintenance is also crucial; adhering to recommended service intervals can prevent costly downtime and ensure that innovations are always at the operator's fingertips. Lastly, training staff on the newest features can maximize efficiency and safety on the job site, further enhancing overall productivity.

Key Technological Advancements in Jack Leg Rock Drill Design and Functionality

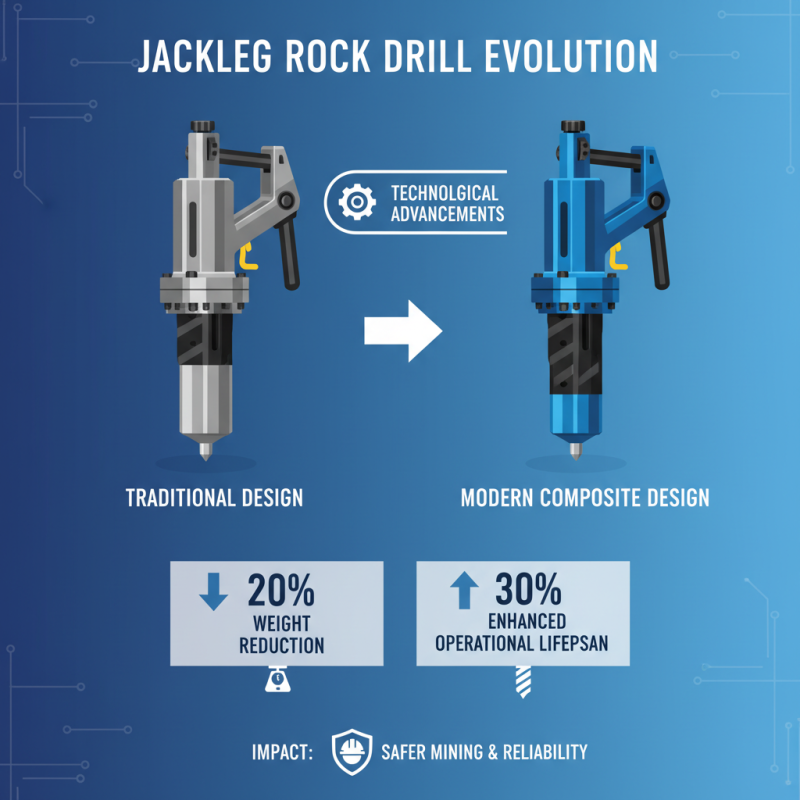

The evolution of jack leg rock drills has witnessed remarkable innovations, particularly in design and functionality, thanks to advancements in technology. Notably, the implementation of advanced materials in the manufacturing process has led to lighter yet more durable drill components. According to a recent industry report, the use of composite materials has enabled a 20% reduction in weight while enhancing the operational lifespan of drill bits by approximately 30%. This is crucial in underground mining operations where worker safety and equipment reliability are paramount.

Moreover, the integration of smart technology into jack leg rock drills has revolutionized their performance metrics. These drills are now equipped with sensors that monitor pressure, temperature, and vibration in real-time, allowing for predictive maintenance that can prevent costly downtime. A study published in the Journal of Mining Science highlighted that mines adopting smart drilling technology saw a 15% increase in efficiency and a 25% reduction in operational costs. Additionally, innovations in ergonomics—like better grip designs and adjustable controls—have improved operator comfort, leading to increased productivity and reduced fatigue during extended use. These advancements reflect the industry's commitment to improving both efficiency and safety in rock drilling operations.

Safety Enhancements in Jack Leg Rock Drilling: New Standards and Practices

Safety in jack leg rock drilling has seen significant advancements in recent years, reflecting the industry's ongoing commitment to protecting workers and enhancing operational efficiency. New safety standards emphasize the importance of rigorous training for all drillers, ensuring that personnel are well-equipped to recognize hazards and respond effectively. Implementing simulation-based training programs allows workers to practice emergency scenarios without the risks associated with actual drilling, thereby fostering a culture of safety on-site.

Moreover, innovative safety features are being integrated into jack leg rock drills themselves. Enhanced visibility through improved lighting systems and sturdy, ergonomic design elements help minimize the potential for accidents during operation. The introduction of automatic shut-off mechanisms in case of equipment malfunction adds an extra layer of security, significantly reducing the risk of injuries. Additionally, regular maintenance routines and comprehensive inspections are crucial in upholding these new safety standards, guaranteeing that the equipment operates as intended and remains compliant with the latest regulatory requirements. By prioritizing safety, the jack leg rock drilling industry can ensure that productivity and worker well-being go hand in hand.

Best Practices for Maintenance and Operation of Modern Jack Leg Rock Drills

Maintaining and operating modern Jack Leg rock drills effectively is critical to enhancing productivity and ensuring safety in mining operations. According to a 2023 industry report by the Mining Equipment Manufacturers Association, routine maintenance can increase equipment lifespan by up to 40%. Regular inspections of wear parts, lubricating moving components, and checking fluid levels are essential best practices to minimize downtime and repair costs. Implementing a preventive maintenance schedule based on manufacturer recommendations can greatly enhance the operational efficiency of these drills.

Furthermore, operator training has shown a significant impact on both performance and safety. The National Mining Association reports that well-trained operators can increase drilling accuracy by 25%, leading to more efficient resource extraction while reducing the likelihood of accidents. Familiarizing operators with the drill's controls, as well as the latest innovations such as automated depth control and vibration reduction technologies, plays a crucial role in optimizing the performance of these machines. Ensuring that all team members understand proper operation techniques and safety protocols not only boosts productivity but also fosters a culture of safety on-site.

Comparative Analysis: Performance Metrics of 2025 Jack Leg Rock Drills

In the rapidly evolving field of mining and drilling technology, the innovations in Jack Leg rock drills for 2025 are designed to enhance operational efficiency and safety. Analyzing the performance metrics of these drills highlights key advancements in their design and functionality. One notable feature is the incorporation of advanced hydraulic systems that improve power output while reducing energy consumption. This is crucial in applications where efficiency directly impacts productivity and operational costs. Moreover, advancements in ergonomic design are evident, with tools being more user-friendly, minimizing strain on operators during extended use.

Performance metrics such as drilling speed, vibration levels, and maintenance frequency have become focal points in evaluating the effectiveness of new Jack Leg models. Comparative analysis shows a marked improvement in drilling speed due to enhanced motor capabilities and improved bit designs, allowing for faster penetration of harder rock formations. Additionally, the reduction in vibration levels contributes to operator comfort and safety, fostering a more productive work environment. Regular maintenance requirements have also seen enhancements, with many new models offering features that facilitate quicker servicing and longer operational life, minimizing downtime. These innovations promise to set new standards in the industry, driving performance to unprecedented levels.

2025 Jack Leg Rock Drill Performance Metrics

Related Posts

-

Top 10 Hand Held Rock Drills of 2025: Your Ultimate Buying Guide

-

What is an Integral Drill Rod? Uses, Benefits, and Types Explained

-

Top 10 Best Vertical Slurry Pumps for Efficient Slurry Management

-

How to Enhance Indoor Air Quality with Advanced Ventilation Machines for Healthier Living Spaces

-

Top 5 Benefits of Using Mini Submerged Pumps for Efficient Water Management

-

Mastering the Jack Hammer Manual: Essential Tips and Techniques for Efficient Use