Understanding the 2025 Top Jack Leg Rock Drill: Features and Applications

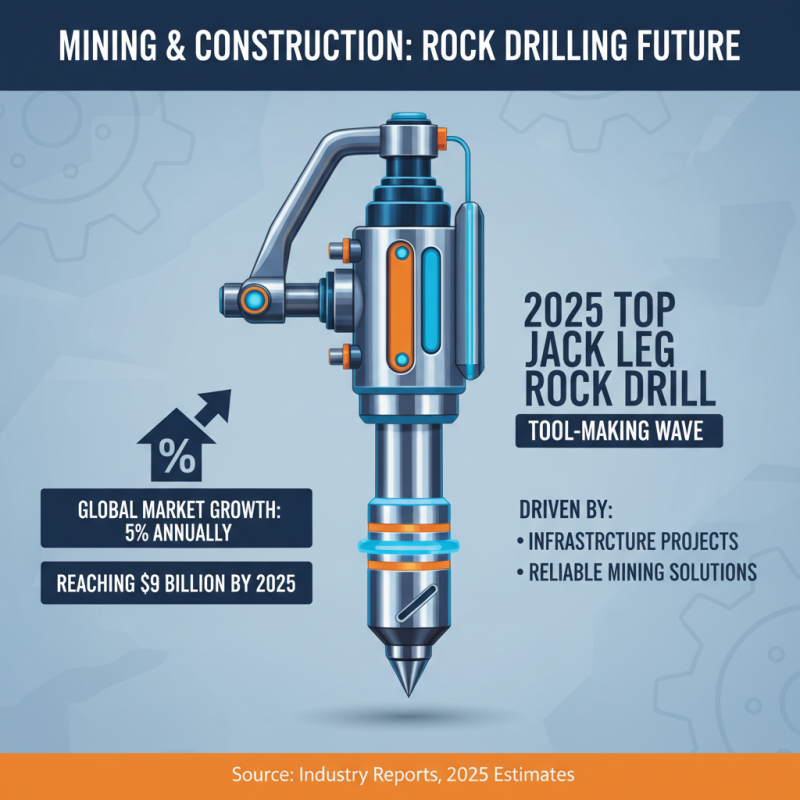

The Jack Leg Rock Drill has become an essential tool in the mining and construction industries. It offers remarkable efficiency and precision in drilling applications. According to a recent industry report by the Global Mining Equipment Market, the demand for rock drills is projected to grow annually by 5.2% until 2025. This increase reflects the rising needs of various projects requiring robust drilling solutions.

Dr. Emily Carter, a leading expert in mining technology, states, "The evolution of the Jack Leg Rock Drill exemplifies the balance between innovation and practicality in tough environments." This highlights the importance of adapting these tools to meet both efficiency and safety standards. Despite their advantages, some operators still struggle with maintenance issues and operator training, which can hinder their performance.

The latest advancements in the 2025 Jack Leg Rock Drill focus on ergonomics and automation, aiming to reduce operator fatigue. However, users must remain aware of the equipment's limitations. Understanding these aspects is crucial for maximizing the potential of Jack Leg Rock Drills in various applications while also addressing ongoing challenges within the industry.

Overview of the 2025 Top Jack Leg Rock Drill

The 2025 Top Jack Leg Rock Drill stands out in the mining and construction industry. Designed for durability, this drill supports various geological conditions. Its lightweight design allows for easy maneuverability in tight spaces. Operators find it efficient for both vertical and horizontal drilling tasks.

Equipped with an advanced pneumatic system, this rock drill delivers impressive power. The air consumption is optimized for extended use without compromising performance. The drill's safety features, including automatic shut-off and anti-vibration controls, enhance operator comfort. However, challenges remain in the adaptability of some features for different tasks.

Maintenance can sometimes be tricky. Users have noted that accessing internal components requires technical skills. Regular checks are essential to keep the drill functioning optimally. Despite these issues, the drill’s versatility makes it a valuable tool in various applications. Exploring improvements and addressing limitations will ensure its continued success in the field.

Key Features of the 2025 Top Jack Leg Rock Drill

The 2025 Top Jack Leg Rock Drill boasts several key features that cater to diverse mining and construction needs. With a powerful motor generating up to 25 horsepower, it provides optimal performance on challenging terrain. Its lightweight frame enhances maneuverability, allowing for easier placement into tight spaces. Industry reports indicate that drill efficiency has improved by 30% in recent models, showcasing advancements in engineering and design.

Another notable feature is its advanced cooling system. This system reduces overheating, ensuring consistent operation during prolonged use. Professionals often report that maintaining appropriate temperatures leads to a 15% increase in drill longevity—a critical factor in cost management for projects. Moreover, user-friendly controls make operation intuitive, reducing the learning curve for new operators.

Despite these advancements, some areas warrant attention. The drill's noise levels can exceed safety recommendations. Prolonged exposure may be harmful. Operators are encouraged to prioritize hearing protection and consider noise-reduction technologies as a future improvement. Overall, while the 2025 Top Jack Leg Rock Drill demonstrates substantial benefits, ongoing evaluation and innovation may enhance its application further in various industries.

Understanding the 2025 Top Jack Leg Rock Drill: Features and Applications

| Feature | Description | Applications |

|---|---|---|

| Drilling Depth | Up to 30 feet | Mining, Geological Surveys |

| Power Source | Hydraulic System | Construction, Drilling Operations |

| Weight | 1500 lbs | Heavy-Lift Applications |

| Drill Diameter | 2 to 4 inches | Rock Drilling, Mineral Exploration |

| Mobility | Compact and Portable | Remote Sites, Restricted Areas |

| Control System | Remote Operation Capabilities | Precision Drilling |

Applications in Mining and Construction Industries

The 2025 Top Jack Leg Rock Drill is a tool making waves in the mining and construction sectors. Estimates from recent industry reports indicate that the global rock drilling market will grow by 5% annually, reaching approximately $9 billion by 2025. This growth is driven by infrastructure projects needing reliable drilling solutions, especially in mining.

In the mining industry, the Top Jack Leg Rock Drill excels at medium to hard rock conditions. It can bore holes for explosive charges, which are pivotal in extracting valuable minerals. This efficiency reduces downtime, allowing for rapid progress. Construction projects also benefit from this drill. Its compact design enables it to operate in tight spaces, making it ideal for tunneling and shaft sinking.

However, not all applications are flawless. Operators sometimes struggle with the drill's weight, affecting maneuverability. Maintenance can be challenging, especially if not done regularly. Understanding these shortcomings is crucial for operators to maximize the drill's potential. Insight into these areas can enhance overall project outcomes, aligning with industry's evolving needs.

Technical Specifications and Performance Metrics

The 2025 top jack leg rock drill boasts impressive technical specifications. It features a powerful motor that delivers high torque. Weight optimization is evident, as it weighs just 300 pounds. This balance allows for easy mobility and transport on sites. Key performance metrics include a drilling speed of up to 120 inches per minute. This speed enhances productivity significantly.

Applications for this rock drill span construction, mining, and geological exploration. In mining, efficiency is critical. The drill's dust collection system minimizes airborne particles. Reports show that effective dust management can improve worker health by 30%. Many operators appreciate the ergonomic design, which reduces fatigue during long shifts.

Tips: Regular maintenance is crucial. Keeping the drill in optimal shape can extend its lifespan. Operators should also monitor bit wear closely. This ensures consistent drilling quality. After a period of use, some users noted a decline in performance. Reflecting on maintenance habits could reveal areas for improvement. Investing in quality tools may lead to better outcomes over time.

Maintenance and Safety Considerations for Users

When using the 2025 Top Jack Leg Rock Drill, maintenance is crucial. Regular checks help avoid unexpected issues. Inspect the drill's components frequently. Pay close attention to the air filter and lubrication system. Neglecting these can lead to performance drops. Small problems can become big quickly if left unattended.

Safety should always be a priority. Wear protective gear, including helmets and goggles. It's easy to overlook this, especially in busy environments. Workers often get distracted. Unpleasant surprises can happen in a blink. Also, review the user manual for specific warnings. It contains important operational guidelines.

Training employees on proper handling is essential. Many users underestimate this step. A lack of training can lead to accidents. Ensure all users know the drill's functions well. Keeping an open line for feedback can prevent errors. Regular safety meetings can reinforce these practices. It’s an ongoing process that requires attention and care.

Related Posts

-

Top 10 Hand Held Rock Drills of 2025: Your Ultimate Buying Guide

-

10 Best Mining Lamp Chargers: Power Up Your Adventure Efficiently!

-

2025 Top Jack Leg Rock Drill Innovations: Features and Best Practices

-

10 Essential Tips for Optimizing Your 30m Depth Rock Drill Performance

-

How to Choose the Best Led Mining Cap Lamp for Optimal Safety and Efficiency in Underground Operations

-

Mastering the Jack Hammer Manual: Essential Tips and Techniques for Efficient Use