Top 10 Benefits of Using a 30m Depth Rock Drill for Your Projects

The use of a 30m Depth Rock Drill can transform various projects. This powerful tool offers numerous advantages that can streamline operations. Whether you’re in construction, mining, or environmental projects, a rock drill can significantly enhance efficiency.

Consider the precision it delivers. It can bore deep into the earth with unmatched accuracy. This greatly reduces the time and effort usually needed for similar tasks. Updated technology allows the drill to handle tough terrains, which is invaluable. It empowers teams to reach challenging rock formations more effectively.

However, not all projects may benefit equally. There are situations where other methods might be preferable. It is essential to assess each project's unique requirements carefully. Ignoring this could lead to unexpected challenges. Thus, while a 30m Depth Rock Drill can be advantageous, careful consideration is crucial for optimal outcomes.

Benefits of Enhanced Drilling Depth for Various Projects

Using a 30m depth rock drill can revolutionize various projects. This kind of depth allows for reaching underground layers that were previously inaccessible. In construction, deeper drilling enhances stability for foundations. It helps engineers create safer structures in challenging terrains.

Another benefit lies in resource extraction. Deeper drills can tap into valuable minerals. This can lead to efficient resource management. However, it does come with challenges. The process may involve higher costs. Also, skill and safety precautions are crucial.

Environmental factors play a role too. Drilling deeper affects ecosystems. Responsible drilling helps mitigate potential impacts. Engaging local communities in discussions can lead to better strategies. Overall, while deeper drilling provides advantages, careful planning is essential.

Top 10 Benefits of Using a 30m Depth Rock Drill for Your Projects

| Benefit | Description | Applicable Projects |

|---|---|---|

| Enhanced Depth Capability | Allows drilling deeper holes, which is essential for geological exploration and mineral extraction. | Mining, Urban Development |

| Increased Efficiency | Faster drilling speeds reduce project time and labor costs. | Construction, Infrastructure |

| Versatile Applications | Suitable for various drilling tasks including geothermal energy extraction. | Energy, Environmental Projects |

| Improved Safety | Advanced technology minimizes the risk of accidents during drilling operations. | Mining, Construction |

| Cost-Effectiveness | Long-term investment with high return due to durability and low maintenance. | Mining, Large Infrastructure |

| Reduced Environmental Impact | Efficient drilling techniques lower the carbon footprint. | Environmental Studies, Geotechnical Engineering |

| Enhanced Data Collection | Facilitates better geological data gathering through deeper drilling. | Geological Surveys, Research |

| Adaptable Technologies | Compatible with various drilling technologies and techniques. | All Types of Drilling Projects |

| Increased Precision | Modern systems enhance the precision of drilling, reducing waste and errors. | Engineering, Hazard Assessment |

| Greater Reach | Ability to drill in challenging terrains that were previously inaccessible. | Remote Areas, Tough Environments |

Increased Efficiency and Speed in Rock Drilling Operations

The use of a 30m depth rock drill significantly enhances efficiency in drilling operations. With powerful torque and advanced features, these drills cut through tough rock quickly. This means less downtime and faster progress on projects. Workers can achieve more in less time, which is crucial in a competitive environment.

Speed is not just about rapid drilling. It also involves minimizing mistakes. Quick operations can lead to oversights. Regular training and monitoring are necessary. Operators must stay sharp. This ensures quality along with speed. Accurate drilling saves resources, making every moment count.

Moreover, increased efficiency leads to cost savings. Projects become more profitable when delays are reduced. Each hole drilled is a step toward project completion. However, it’s essential to balance speed with safety. High speed shouldn't compromise worker safety. Reflection on operational methods is vital for improvement. It’s all about fine-tuning the process to achieve the best results.

Top 10 Benefits of Using a 30m Depth Rock Drill for Your Projects

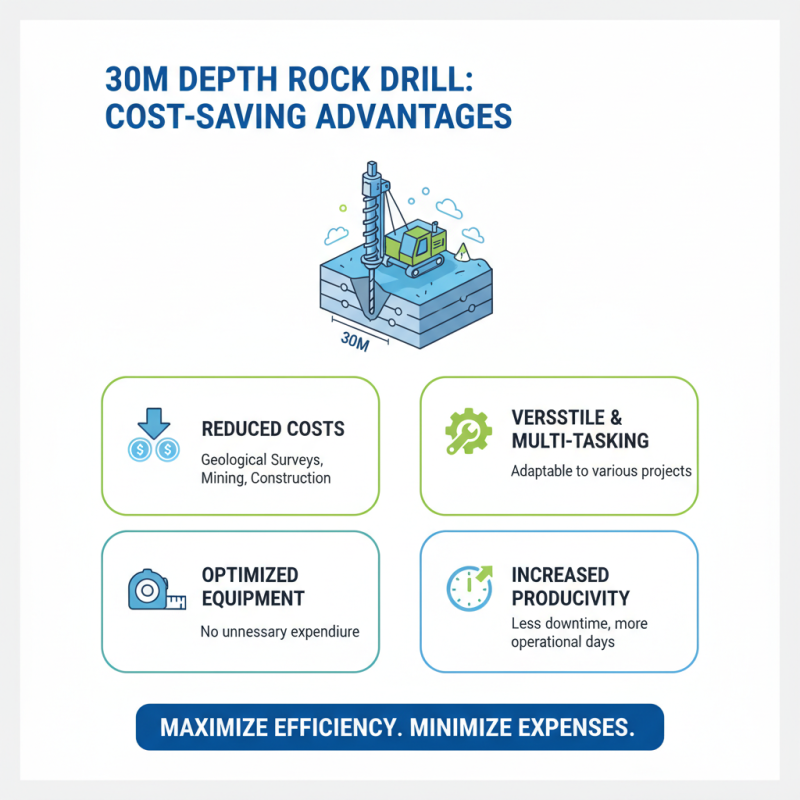

Cost-Effectiveness of Using 30m Depth Rock Drills

Using a 30m depth rock drill can significantly cut costs in various projects. These drills are versatile. They can tackle multiple tasks, from geological surveys to mining operations. When you choose a rock drill tailored for a specific depth, you prevent unnecessary expenditure on equipment. Also, reduced downtime leads to more productive days on site.

Labor costs also tend to decrease with efficient rock drills. Operators can drill faster and more accurately. This efficiency can lead to fewer errors and less rework. However, it's crucial to ensure that the team is adequately trained. Lack of expertise can offset potential savings. Moreover, while these drills offer cost benefits, they require maintenance. Neglecting maintenance can lead to increased long-term costs. Regular check-ups and minor repairs can save a lot in the future.

Investing in a 30m rock drill seems attractive, but be cautious. Analyze project requirements before committing. Sometimes, smaller drill options might suffice. Nonetheless, for deep and challenging projects, the cost-effectiveness of these drills shines through, provided they are used correctly and maintained well.

Versatility of 30m Rock Drills in Different Industry Applications

30m depth rock drills are gaining traction across various industries. Their versatility allows teams to tackle a range of projects, from construction to mining. According to a report by the International Journal of Advanced Robotics Research, the demand for advanced drilling solutions has surged by 25% in the last five years.

In the construction sector, these drills play a vital role. They can penetrate hard geological formations while minimizing vibrations. This is crucial in urban areas where nearby structures might be affected. Reports indicate that 70% of urban drilling projects face challenges due to unsuitable equipment. A 30m rock drill can address these issues effectively, yet improper use can lead to inefficiencies.

Mining operations also benefit significantly from these solutions. The ability to reach depths of up to 30 meters means increased resource extraction. A recent mining industry survey showed that 80% of professionals find that versatile drills improve their productivity. However, challenges remain in ensuring that operators are trained adequately. Skilled labor shortages mean that projects sometimes face delays. Failing to address this can result in increased costs and unmet deadlines.

Improved Safety Features of Modern Rock Drilling Equipment

Modern rock drilling equipment has significantly improved safety for operators. Improved safety features include advanced visibility systems and ergonomic designs. For instance, a study by the International Council on Mining and Metals found that proper visibility can reduce accident rates by up to 30%. This is crucial in environments where depth work, like 30m drills, is common.

Another key aspect is the integration of automatic shut-off systems. These systems are designed to detect anomalies. They can halt operations before accidents occur. A report from the National Institute for Occupational Safety and Health states that 70% of drill-related injuries are preventable with such technology. Additionally, modern drills often include enhanced vibration dampening, reducing the strain on operators. This can lead to lower instances of long-term injuries.

Despite these advancements, challenges remain. Some operators may still overlook safety protocols. Training programs need to be reinforced to ensure all staff are aware of the equipment's features. Moreover, the initial cost of these advanced safety features can be a barrier for some companies. Balancing safety and budget concerns requires ongoing dialogue in the industry.

Related Posts

-

10 Best Mining Lamp Chargers: Power Up Your Adventure Efficiently!

-

Exploring the Benefits of Portable Ventilators: Your Guide to Respiratory Relief Anytime, Anywhere

-

Top 10 Hand Held Rock Drills of 2025: Your Ultimate Buying Guide

-

Why Invest in Mining LED Headlamps for Enhanced Safety and Efficiency?

-

Mastering the Jack Hammer Manual: Essential Tips and Techniques for Efficient Use

-

Maximizing Efficiency: Why Integral Drill Rods Are Essential for Modern Drilling Techniques