10 Essential Tips for Optimizing Your 30m Depth Rock Drill Performance

In the competitive world of geological exploration and construction, optimizing equipment performance is crucial for efficiency and safety. Renowned industry expert Dr. Michael Tanner, a geotechnical engineer with over two decades of experience in drilling operations, emphasizes that "the key to maximizing the output of a 30m Depth Rock Drill lies in understanding both the technology and the terrain." His insights underline the importance of meticulous preparation and strategic execution when it comes to utilizing rock drills effectively.

As the demand for rock drilling increases across various sectors, professionals must hone their skills and adapt best practices to enhance the performance of their 30m Depth Rock Drill. This optimization not only leads to quicker project completion but also minimizes costs and resource wastage. By implementing the right techniques and maintaining equipment, operators can ensure that their drilling tasks are executed with precision, reducing downtime and enhancing overall productivity.

This article presents ten essential tips for optimizing your 30m Depth Rock Drill performance. From selecting the appropriate drill bits to understanding geological formations, these strategies will equip drill operators with the knowledge necessary to elevate their performance and achieve outstanding results in their drilling endeavors.

Understanding the Basics of 30m Depth Rock Drills

Understanding the basics of 30m depth rock drills is crucial for any operation involved in geotechnical or mineral exploration. These drills are designed to penetrate hard rock layers, typically ranging from granite to basalt, and are instrumental in extracting soil and rock samples. Reports from the International Society for Rock Mechanics indicate that the efficiency of drilling tasks significantly depends on factors such as drill bit type, weight on bit (WOB), and rotational speed, which can enhance the core recovery rate by as much as 20%.

One essential tip for optimizing performance is to select the correct drill bit. For instances where you encounter varying rock types, using a tri-cone or diamond bit can reduce wear and improve penetration rates. Another vital tip involves maintaining the correct WOB. Operators should ensure that the applied weight is not excessively high, as this can lead to premature bit failure. Keeping the WOB at an optimal level—often around 50-70% of the equipment's maximum capacity—can significantly enhance both the lifespan of the bit and the efficiency of the drilling process.

Additionally, adhering to regular maintenance schedules for your rock drill is key for longevity and reliability. A comprehensive maintenance plan that includes checks on hydraulic systems and drill components can prevent unexpected breakdowns. Industry reports suggest that regular maintenance can reduce downtime by nearly 30%, providing a clear pathway to sustained operational efficiency in rock drilling projects.

10 Essential Tips for Optimizing Your 30m Depth Rock Drill Performance

| Tip | Description | Expected Improvement (%) |

|---|---|---|

| Regular Maintenance | Ensure the drill is serviced regularly to avoid breakdowns. | 15% |

| Proper Bit Selection | Choose the correct bit type for the rock formation. | 20% |

| Optimize Drilling Speed | Adjust speed based on rock type to improve efficiency. | 25% |

| Use Quality Drill Fluids | Select appropriate drill fluids to enhance cooling. | 18% |

| Monitor Performance | Track performance metrics to identify areas for improvement. | 10% |

| Train Operators | Ensure operators are well-trained for optimal performance. | 30% |

| Adjust Weight on Drill | Modify weight to match rock hardness for better penetration. | 22% |

| Reduce Idle Time | Minimize downtime during operational hours to boost output. | 12% |

| Check Alignment Regularly | Ensure the drill is properly aligned at all times. | 15% |

| Upgrade Equipment | Invest in modern drills and equipment technologies. | 35% |

Key Factors Affecting Rock Drill Performance

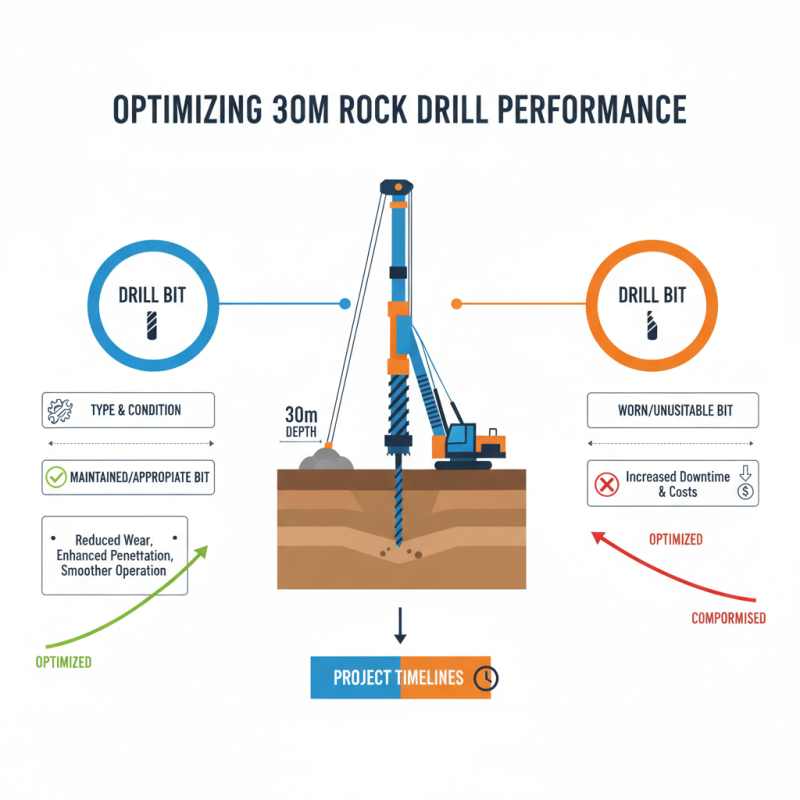

When optimizing the performance of a 30m depth rock drill, several key factors play a crucial role. Firstly, the type and condition of the drill bit significantly influence drilling efficiency and longevity. A well-maintained, appropriate bit can reduce wear and enhance penetration rates, ensuring smoother operation. Conversely, using a worn or unsuitable bit can lead to increased downtime and costs, undermining project timelines.

Another critical factor is the drilling parameters such as weight on the bit, rotation speed, and feed rate. Experimenting with these parameters can help identify the optimal settings for specific geological conditions. For instance, adjusting the weight on the bit can improve the rate of penetration, ensuring a more efficient drilling process. Additionally, monitoring and adapting the drilling fluid properties can help maintain stability and cooling during operations.

Lastly, regular maintenance of the rock drill equipment is indispensable. Routine checks and timely repairs can prevent unexpected failures and enhance overall performance. Incorporating these tips, like maintaining a clean drilling environment and ensuring proper lubrication, can further improve the drill's efficacy, making certain each project reaches its potential without unnecessary complications.

Techniques for Enhancing Drill Bit Efficiency

Maximizing the efficiency of drill bits is crucial for achieving optimal performance in 30m depth rock drilling operations. According to a report published by the International Journal of Mining Science and Technology, the choice of drill bit material and design directly impacts penetration rates and overall drilling efficiency. For instance, carbide and polycrystalline diamond compact (PDC) bits have been shown to improve penetration rates by up to 40% in hard rock formations compared to traditional steel bits. Adopting advanced materials not only increases durability but also enhances the bit's ability to withstand the extreme conditions encountered at greater depths.

Another significant factor to consider is the drill bit's geometry. Studies from the Society for Mining, Metallurgy & Exploration indicate that optimizing the shape and size of drill bit components can lead to reduced friction and improved chip removal, crucial for maintaining efficiency during drilling. For example, incorporating variable helix angles can facilitate faster drilling speeds while minimizing vibration, which is essential for accurate borehole placement. Furthermore, regular maintenance and inspection of drill bits help identify wear patterns and allow for timely replacements or adjustments, ultimately prolonging the life of the equipment and enhancing overall performance in the field.

Drill Bit Efficiency Comparison

Maintenance Practices for Optimal Drill Longevity

Maintaining a rock drill is critical for ensuring optimal performance and longevity, especially when operating at depths of 30 meters. Regular maintenance practices not only prevent downtime but also enhance the overall efficiency of the drilling process. According to a report by the International Society for Rock Mechanics, preventive maintenance can reduce equipment failures by up to 40%, thereby increasing productivity significantly. This underscores the importance of adhering to a strict maintenance schedule that includes routine inspections, lubrication, and prompt replacement of worn parts.

One of the key maintenance practices is the careful monitoring of hydraulic fluid levels and quality. The Society for Mining, Metallurgy & Exploration has highlighted that contaminated fluid can lead to premature wear and damage to the drill's hydraulic components. Additionally, ensuring that drill bits are sharpened and replaced as needed can improve penetration rates by as much as 25%, as evidenced by field studies. Implementing these maintenance strategies not only prolongs the life of the drill but also enhances operational safety, ultimately resulting in more efficient drilling operations.

Safety Considerations When Operating Rock Drills

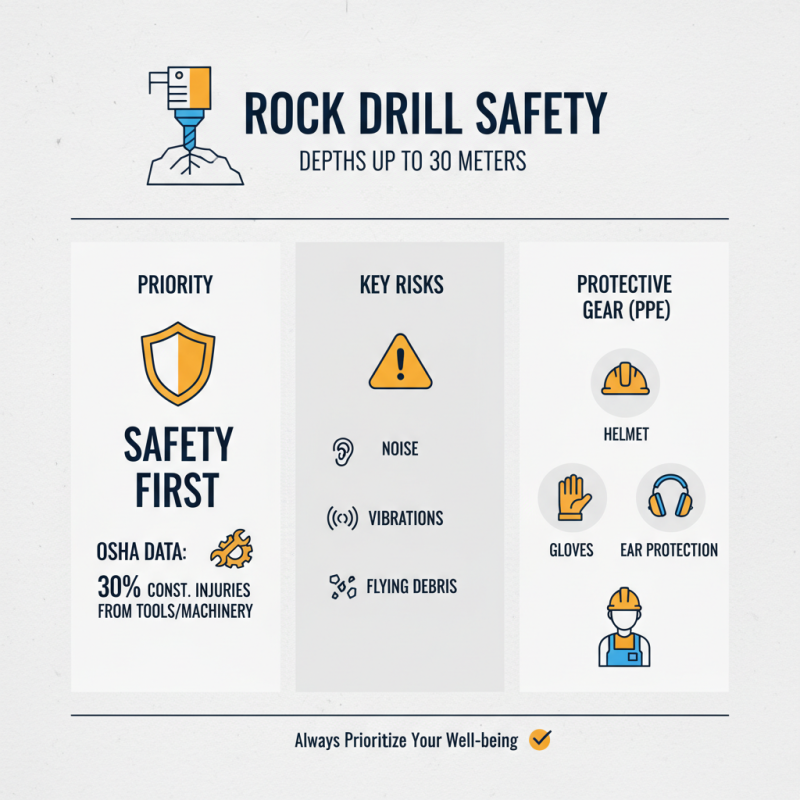

When operating rock drills, particularly those designed for depths up to 30 meters, safety considerations should always take precedence. According to the Occupational Safety and Health Administration (OSHA), nearly 30% of workplace injuries in construction involve hand tools and machinery, highlighting the need for stringent safety measures. Operators must wear appropriate personal protective equipment (PPE) such as helmets, gloves, and ear protection to mitigate risks associated with noise, vibrations, and flying debris.

Before initiating drilling operations, it's crucial to perform a thorough inspection of the rock drill and surrounding environment. This inspection should include checking for gas hazards, ensuring proper ventilation in enclosed spaces, and evaluating the stability of the drilling site. Implementing these safety checks can reduce the likelihood of accidents by up to 50%, as reported by the National Institute for Occupational Safety and Health (NIOSH).

Additionally, maintaining a clear communication protocol among team members is vital. Establishing hand signals or using two-way radios can help prevent misunderstandings, particularly in noisy settings. Operators should also be familiar with the drill's safety features and emergency shutoff mechanisms. Inadequate knowledge of equipment operation has been shown to contribute to 80% of drill-related accidents, as noted in various industry reports. By prioritizing safety through proper training and adherence to guidelines, drill operators can significantly enhance their operational performance while minimizing risks.

Related Posts

-

How to Improve Indoor Air Quality with Ventilation Machines for Healthier Living Spaces

-

Maximizing Efficiency: Why Integral Drill Rods Are Essential for Modern Drilling Techniques

-

Mastering the Jack Hammer Manual: Essential Tips and Techniques for Efficient Use

-

The Ultimate Guide to Choosing the Best Electric Rock Drill for Your Projects

-

How to Choose the Best Led Mining Cap Lamp for Optimal Safety and Efficiency in Underground Operations

-

Exploring the Industry Trends of Jack Hammer Manual at the 2025 China Import and Export Fair